The Design Process

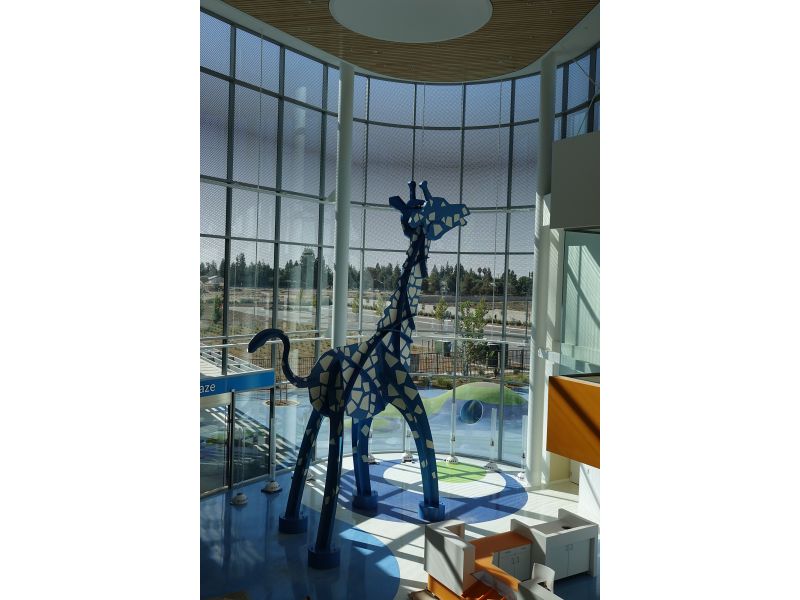

Each sculpture is designed and cut to precise specifications with a plasma cutter into plate steel and stainless steel. During the welding process, exact engineering of the balance and symmetry of the animal heads gives them the ability to move in the wind, creating kinetic sculpture. However, in the case of the 2 children's hospitals a motor was designed for the head to move, since they were placed in atriums and they were 30 feet tall.

An individual sculpture can have as many as twenty steel parts that are welded together to create the whole magical sculpture. After careful inspection of each weld, the sculpture is sand blasted to prepare the steel for the next process. Each sculpture will then be given either a rust patina or be powder coated in brilliant color.

Sustainability

The brightly colored sculptures are first given a zinc primer, then a colored base powder coat, and may include as many as four multiple layers to acheive different colors on one sculpture. The final coat is a clear coat with UV protection.

Pricing

Pricing depends on the size of the sculpture. The 30' Giraffe is $350,000.